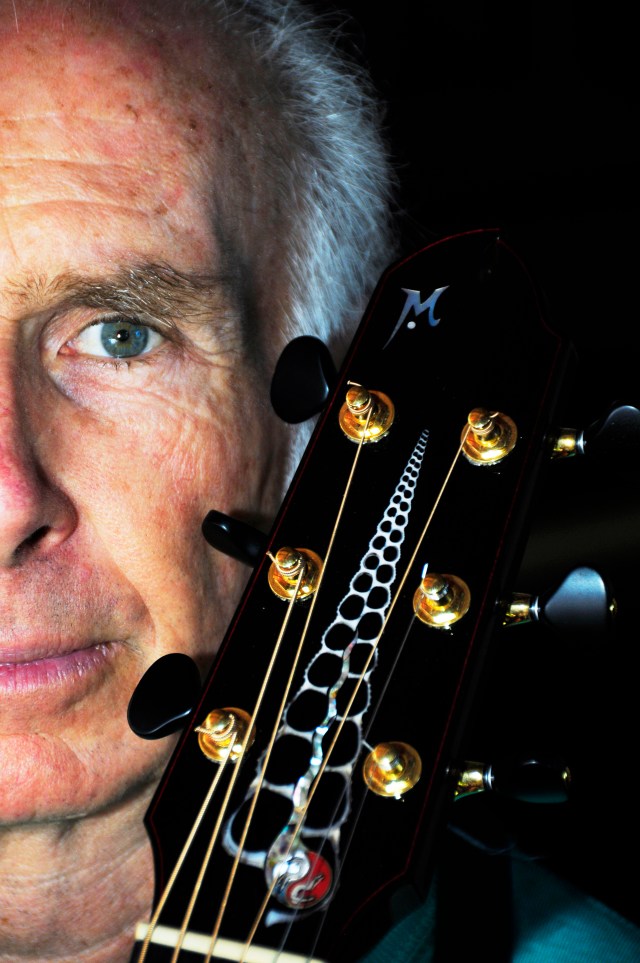

Rosewood Rhythm

Marc Maingard lifts a thin piece of wood to his right ear and taps it with the middle finger of his left hand. Once… Twice… He’s been smiling since the first tap, but I only hear it on the third. A musical note reverberates across his workshop, audible above the waves crashing onto Scarborough beach, a few hundred metres away.

Maingard is a luthier and produces hand-crafted guitars, regarded by musicians and collectors alike as some of the finest in the world. What sets him apart is his ability to coax the finest tones from the wood he uses to make his instruments – and the fact that he can tell from the first tap of a raw guitar top whether its up to scratch or not, is a sign of his mastery of the craft. He had been making ‘passable’ guitars for 14 years when one day, he held a piece of wood to his ear and tapped it – and it all made sense. “The universe aligned and I ran around the workshop tapping pieces of wood like crazy, hearing a whole new world of sounds. I knew then that I had gained the knack of being able to tell exactly what I’d need to do to a particular piece of wood to make it into a great guitar, and I’ve fortunately never looked back”.

Guitar Legend

Maingard has put his name to over 330 guitars in his career to date, producing up to 24 custom instruments a year at prices topping R100 000. His guitars are made-to-measure for clients who know quality when they see it – and hear it. Crosby, Stills & Nash’s Steven Stills has described Maingard as “the best guitar-maker in the world” and clients fly in from Japan and the US to meet the guitar guru at his home studio and select finishes including gold, diamonds, abalone and pearl for their custom instruments.

Barefoot and ponytailed, Marc radiates a sense of calm which has helped him build his reputation over the course of more than 40 years. He’s been playing guitar for even longer than that, and got into guitar-making when one of his own instruments was damaged on an international flight and the luthier he sent it to for repairs, botched the job. He took the instrument apart and patched it up again himself – surprising himself and impressing musician friends in the process. Word spread and a steady flow of repair requests saw him building both his repertoire and reputation. Learning from books ordered in from far-flung places and traveling to learn in the workshops of master luthiers in the US, Maingard worked his way through apprenticeships to becoming a full-time guitar-maker.

Magic Wood

His premier instruments are made from a stock of incredibly rare Brazilian Rosewood that he picked up decades ago. This mind-bogglingly expensive wood – almost impossible to source nowadays – produces the best tones and delivers an investment guitar that should last hundreds of years if stored correctly. “A hand-crafted guitar with a European spruce top and Brazilian rosewood back and sides shows amazing notational separation – whereas a mass-produced guitar delivers notes in clumps”, he says. Maingard guitars deliver colourful tones with better volume and clarity than a mass-produced model – making him the go-to choice for musical cognoscenti. “If you could afford a Porsche, you’d probably buy one – but that doesn’t make you a racing driver,” says Maingard. “One of my guitars isn’t going to make you a better player, but it will open your ears to a musical spectrum that you’d probably struggle to access, otherwise”. His signature ‘Maingard Bevel Edge’ makes for a more comfortable playing experience and adds 25 hours to the production of a single instrument – but a worthwhile difference, easily apparent to even a novice.

Sound Investment

You’d think a global recession would put a kink in the R100 000 guitar market, but the downturn has only increased the value of Maingard’s instruments. “Having my guitars moving into the collectible space has been a great honour for me,” he says. “Some of my clients have been forced to put their guitars on the market and they’ve been snapped up by agents who are then able to seek out other collectors who are willing to pay top dollar for hand-crafted instruments”.

“I have a particular sound that people come to me for – my guitars are built for playability, comfort and sound,” says Maingard. “My market is comprised of people who know what they are looking for. Each instrument is unique – tuning the body of a guitar is something you learn by experience. It’s not a given that two pieces of wood cut from the same stock will make two guitars that sound identical – two bakers with identical ingredients will make two different loaves of bread”.

Keeping it Authentic

He’s had offers to put his name to assembly-line guitars produced in massive factories in the US and China which would have made him a household name along the lines of Gibson, Martin and Fender, but Maingard says it took him less than 5 minutes to say ‘no’ to the lucrative deals. “I saw a Maingard clone in America once – it was a very convincing copy but it sounded terrible. I decided that I couldn’t put my name to something that I hadn’t built myself and that was the end of it. Each instrument takes upwards of 80 hours to build by hand and I wouldn’t have it any other way”.

Taking to the Stage

Even when he’s not working, Marc finds it hard to put down a guitar and often takes to the stage with his son Nate, a professional musician. He’s a virtuoso player – and it’s an honour to hear the man play one of his own instruments. Art, science, skill and intuition combine in very few places – but Maingard seems to have yoked them with the tap of that middle finger on rosewood.

*A version of this article was published in Private Edition.